Combined systems

flexcmw

The most compacted and economic option of the market for a wide product control at the end of the line.

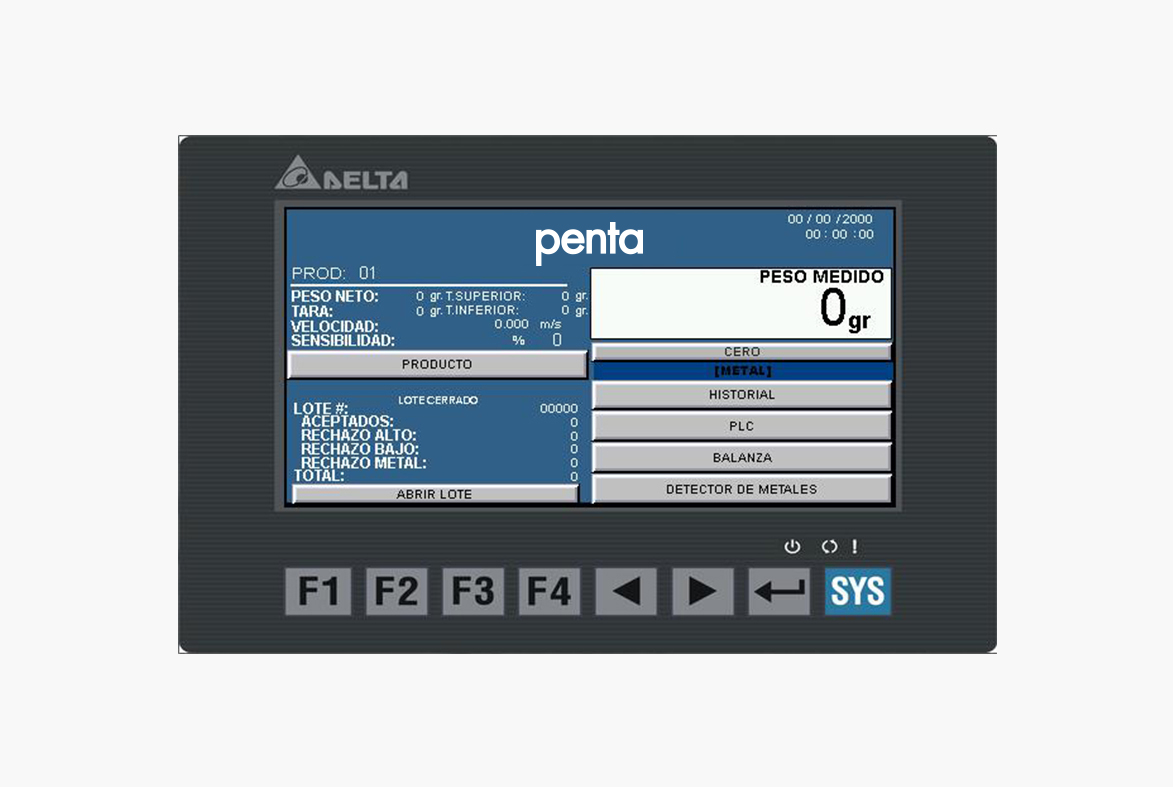

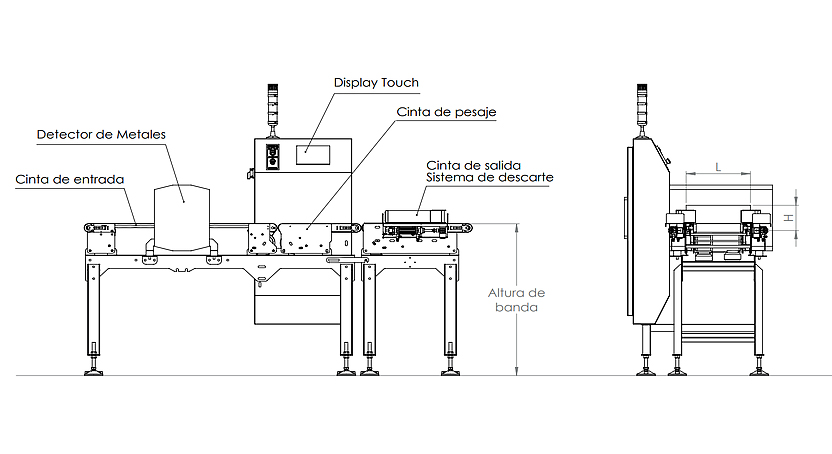

- A design which combines metal detectors and dynamic weighing in the same transporter with the command interface and common rejection system

- Command interface through a touch screen

- Software for statistic production control and report generation

- Multiple available rejection systems

- Maximum saving space in the plant

- Less investment requirement

- Minor spare stock and maintenance requirements

Fact Sheet

SPECIFICATIONS

| MODELS | ||

|---|---|---|

| CW 300 | CW 450 | |

| Weighing Range | 25-3000 gr | |

| Minimum Display Division | 0.1 gr | |

| Accuracy (grs)* | +/- 0.5 gr * | |

| Max Production (Units/Min) | 200 | 140 |

| Max Product Length (mm) | 190 | 340 |

| Conveyor Width L (mm) | 190-240-290 | |

| Conveyor Type | Continuous | |

| Detector Window Height (mm) | 100-150-200-250 | |

| Detector Window Width (mm) | 200-350-500 | |

| Automatic Rejection | Blower / Flipper / Pusher Piston | |

| Screen Height (mm) | 900 - 1300 | |

| Working Temperature (ºC) | 0º to 50º C | |

| IP Protection | IP-54 (optional IP-65) | |

| Finish | Blasted AISI 304 Stainless Steel | |

| Power Supply Voltage | 1x220V/3x380V | |

| Power Supply Frequency | 50/60 Hz | |

| Required Air Pressure | 4kg/cm2 | |

| Screen and Control | 7” TOUCH Display (color) | |

(*) Final operational accuracy will depend on product weight and production speed.

SPECIFICATIONS

| MODELS | |||

|---|---|---|---|

| CW 550 | CW 650 | CW 850 | |

| Weighing Range | 0.5-25 kg | ||

| Minimum Display Division | 1 gr | ||

| Accuracy (grs)* | +/- 1 gr * | ||

| Max Production (Units/Min) | 65 | 55 | 42 |

| Max Product Length (mm) | 440 | 540 | 740 |

| Conveyor Width L (mm) | 300-450 | ||

| Conveyor Type | Modular | ||

| Detector Window Height (mm) | 200-250-300-350 | ||

| Detector Window Width (mm) | 350-500-700 | ||

| Automatic Rejection | Pusher Piston | ||

| Screen Height (mm) | 900 - 1300 | ||

| Working Temperature (ºC) | 0º to 50º C | ||

| IP Protection | IP-54 (optional IP-65) | ||

| Finish | Blasted AISI 304 Stainless Steel | ||

| Power Supply Voltage | 1x220V/3x380V | ||

| Power Supply Frequency | 50/60 Hz | ||

| Required Air Pressure | 4kg/cm2 | ||

| Screen and Control | 7” TOUCH Display (color) | ||

(*) Final operational accuracy will depend on product weight and production speed.

SPECIFICATIONS

| MODELS | ||

|---|---|---|

| CW 850 | CW 1200 | |

| Weighing Range | 2-75 kg | |

| Minimum Display Division | 0.01 kg | |

| Accuracy (grs)* | +/- 10 gr * | |

| Max Production (Units/Min) | 60 | 50 |

| Max Product Length (mm) | 740 | 1090 |

| Conveyor Width L (mm) | 450-650 | |

| Conveyor Type | Continuous / Modular | |

| Detector Window Height (mm) | 300-350-400-450-500 | |

| Detector Window Width (mm) | 500-700 | |

| Automatic Rejection | Pusher Piston | |

| Screen Height (mm) | 900 - 1300 | |

| Working Temperature (ºC) | 0º to 50º C | |

| IP Protection | IP-54 (optional IP-65) | |

| Finish | Blasted AISI 304 Stainless Steel | |

| Power Supply Voltage | 1x220V/3x380V | |

| Power Supply Frequency | 50/60 Hz | |

| Required Air Pressure | 4kg/cm2 | |

| Screen and Control | 7” TOUCH Display (color) | |

(*) Final operational accuracy will depend on product weight and production speed.

360° View

Keep the mouse pressed on the image and rotate the pointer to visualize our equipment at 360°.

Do you need service or any supply?

Our professional staff can help you